CuMo Project

The CuMo Project, discovered in the 1960’s, has undergone numerous drilling and exploration campaigns along with related permitting efforts. Located partially on unpatented federal mining claims in the Boise National Forest, permits are needed from the US Forest Service (USFS) to conduct drilling, roadwork, and related actvities. The last drilling campaign finished in 2012, and subsequently the Company applied to the USFS for additional exploration permits, which were granted. These permits were challenged by non-governmental organizations (NGO’s) in two separate lawsuits, which forced the Company to perform additional studes and technical work.

In March 2025 the Company received a Decision Notice and Finding of No Significant Impact (FONSI) from the US Forest Service, approving Idaho Copper’s 4-year Exploration Plan of Operations. In June 2025 the NGO’s again brought a lawsuit seeking to overturn the decision of the USFS. This litigation is ongoing but Idaho Copper believes that the position of the NGO’s is without merit, and that drilling on these federal mining claims will be able to begin in 2026.

As the Idaho Copper Project moves forward, having Idaho-based operations and leadership will provide greater access to relevant agencies and help to build state, local and community relationships. The ongoing engagement of Idaho professionals, local labor, geologists, and mining industry experts confirms IC’s commitment to Idaho and Boise County.

The Idaho Copper exploration team maintains best management practices with respect to groundwater, hydrogeology and environmental protection in conducting its federally approved activities on private and public lands.

The Project region, Southern Idaho, is rooted in mining history and natural resource economies. A recent survey by Boise State University highlighted the overwhelming support of Idahoans for responsible mining with 80.4 percent of respondents affirming their belief that mining can be conducted without negatively impacting the environment. Local, state and federal governments have shown great interest in and are formally declaring their support for the Idaho Copper Project. Furthermore, a shift to pro-development policies within federal agencies has created momentum for strategic minerals projects.

Path to Value Creation

Step 1

Updated Preliminary Economic Assessment (PEA)

Focus on ore sorting evaluation and testing to eliminate waste and reduce mill size and capital and operating costs.

Step 2

Drilling / Resource Update

Upon receiving final drill permits, the potential for resource expansion via drilling in higher grade copper area to the west, plus infill drilling in the previously explored areas.

Step 3

Phase 1 Improvements

Smaller starter pit in higher-profit areas developed through ore sorting to be analyzed in order to optimize early cashflow.

Step 4

Leaching Potential

Potential to stockpile and heap leach lower-grade ore which otherwise would be sent to the concentrator, adding to cashflow.

Step 5

Pre-Feasibility Study (PFS) Increases Shareholder Value

Upgraded PEA to PFS study with increased efficiencies on phase 1 development.

What is ore sorting?

Ore-sorting is a process for upgrading mineral bearing rock. Current technology supplies three different types of ore sorting: Bulk, Conveyor and Particle. Current studies indicate Idaho Copper will most likely use a combination of the three types of sorting in order to improve mill feed grades and potentially lower costs.

Types of ore sorting:

• Bulk ore sorting

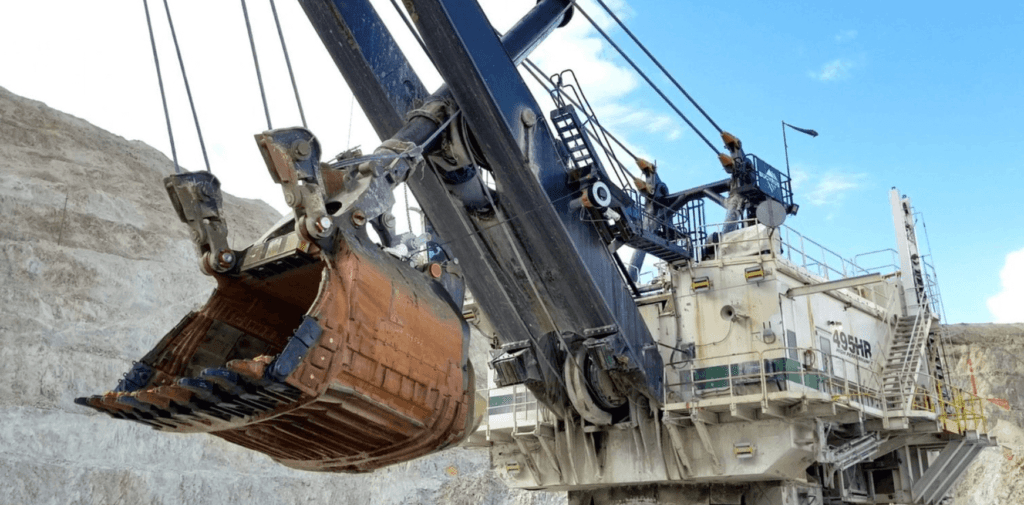

Bulk sorting involves two distinct areas: namely blast control and bucket scanning. In blast control areas of waste and sort/mill feed can be separated by controlled blasting such that material can be separated into zones based on grade. Bucket scanning involves using X-Ray Fluorescent (XRF) sensors placed in the load bucket of a shovel. The material can then be directed to the appropriate location based on the grade value of the entire bucket. ShovelSense technology manufactured by MineSense is currently being successfully used in existing large-scale, open pit operations to separate material and improve mill feed.

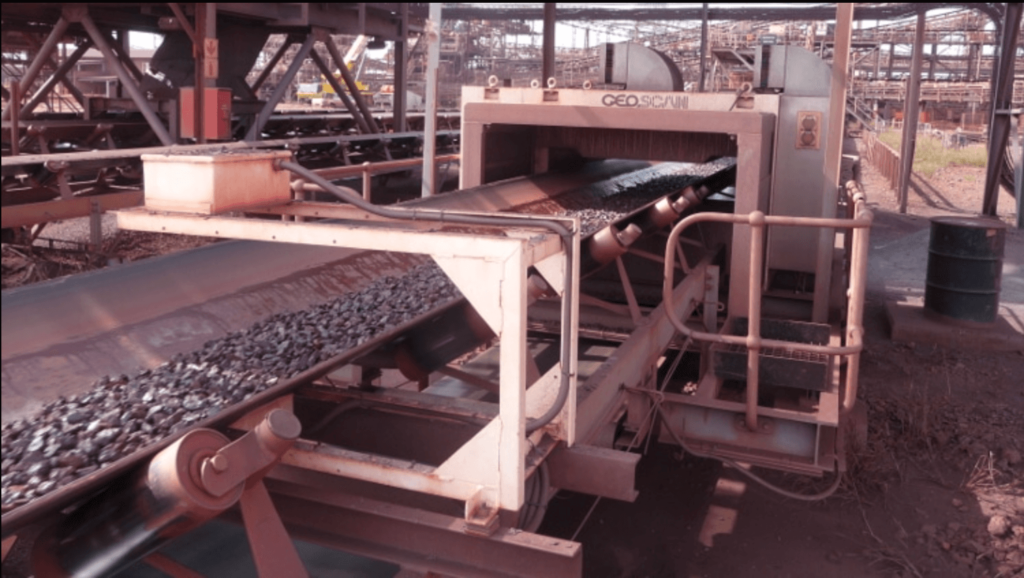

• Conveyor ore sorting

Conveyor sorting involves scanning crushed material on a conveyor belt or within a shovel load, using various scanning techniques to identify the grade of bulk sections of the mined material. For example, bulk sorters are currently in operation that can scan material crushed at 60 mm size (2.5 inches) at the rate of 5,000 tons per hour using Prompt Gamma Neutron Activation Analysis scanner (PGNAA).

This allows the feed to be divided into blocks /packets of various sizes depending on the width and speed of the conveyor belt and the scan time. The material can then be separated using flow diverters into three grades waste, middlings and mill feed. Middlings can be forwarded for additional finer level sorting.

• Particle ore sorting

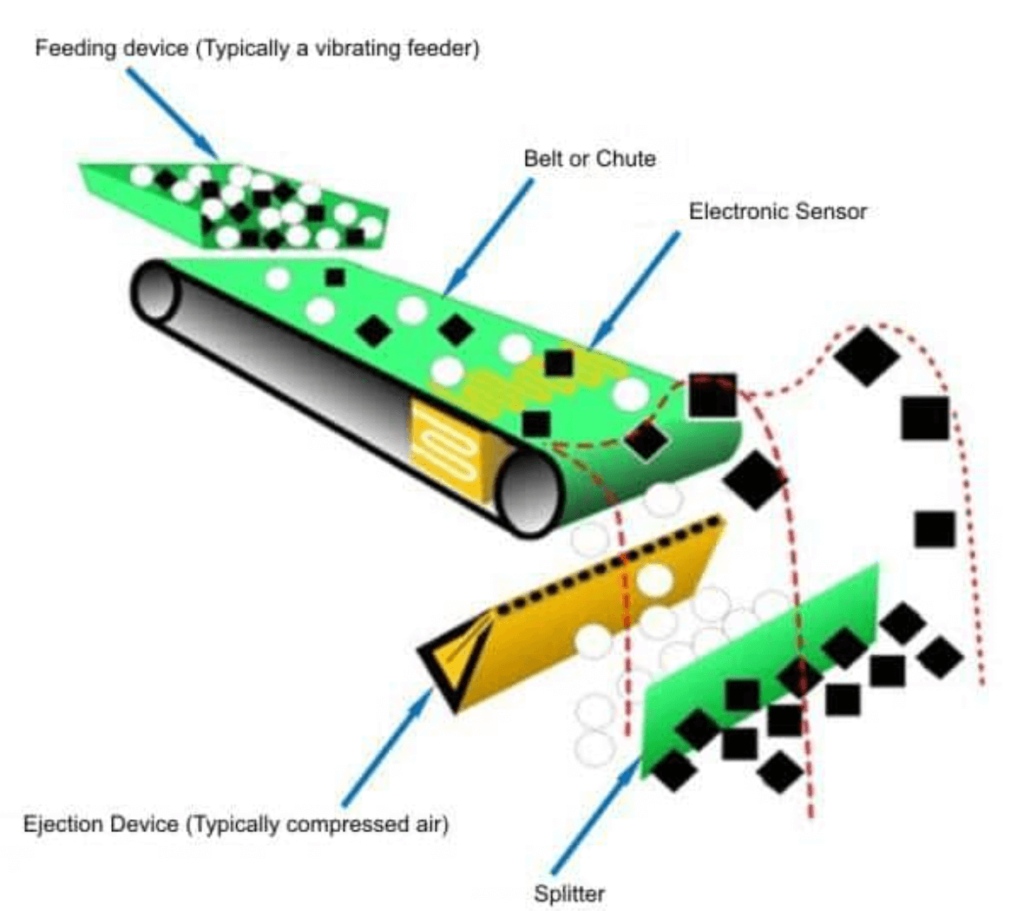

Particle sorting is typically between 250mm and 10mm (1 to 4 inches) and involves evaluating the mineral content of individual rocks as they pass through a sensor then separating them into Accept and Reject fractions, based on pre-determined selection criteria.

Why does ore sorting work on Idaho Copper?

Geological zones vary from 0% to 40% of the material containing the grade. The examples below show a drill intersection on the edges of the molybdenum core zone. Use the radio buttons to turn the sorting on and off.

The section from Hole 11-59 from 1630 to 1640 feet assayed 0.175% MoS2. note: US$/ton is an Recovered Value as used in independent 43-101 report.

Unsorted

Sorted

Approximately 10% of the interval contains the actual molybdenum veins which are dark grey to black in the picture. The core boxes are 2 feet long. Breaking it into 2 to 3 inch pieces is done to simulate primary crushing. Sorting would initially identify the mill feed (red – 22.5%) within the interval and that would be mill feed, secondary sorting would identify the stockpile (yellow – 30.5%), and remaining material is waste (blue – 47%). This would result in a grade of 0.583% MoS2 for the mill feed, and 0.134% MoS2 for the stockpile.

Interactive Model

We invite our audience to view up-to-date assay results and geology zones via our Proprietary Interactive Model.

This model contains:

- Actual drill hole data

- Geological model of the deposit

- Copper, molybdenum and silver resource values

- Grade layers

View the resource and geology models in various formats:

- 3D viewer

- Cross-Section

- Long-Section

- Plan-Section

Instructions:

- The Unity Engine Web Player runs the interactive model. You will be asked to install it the first time you choose to run the model.

Please allow the Unity Engine to install on your computer. - You will be redirected to another site to use the CuMo Project Interactive Model. It will not display on smart phones.

- Use the mouse and arrow keys to select which model to view and to specify drill assay results or geology zones.

Engineering Studies

Preliminary Economic Assessment & NI 43-101 Technical Report for the CuMo Project, USA

Resource Estimate Update June 2011, Updated June 2012

2015 Summary Report on CuMo Property, Boise County, Idaho

CuMo Mo-Cu-Ag Deposit, a 21st Century Mega-Deposit

CuMo Project Throughput Scoping Study Report

Summary Report on the CuMo Property, Boise County, Idaho

Title

Type

By

Date

Doc

Preliminary Economic Assessment & NI 43-101 Technical Report for the CuMo Project, USA

43-101

PEA

SRK

Gary Giroux, P.Eng

Sacre Davey Engineering

June 2020

Resource Estimate Update June 2011,

Updated June 2012

43-101

Resource Estimate

Snowden Mining Consultants

June 2012

2015 Summary Report on CuMo Property,

Boise County, Idaho

43-101

Resource Estimate

Gary Giroux, P.Eng.,

Shaun M Dykes, P.Geo.,

and James H Place, P. Geo

November 2015

CuMo Mo-Cu-Ag Deposit,

a 21st Century Mega-Deposit

Presentation to 2009

NWMA Conference

Dykes, Ball and Garshelis

CuMo Project Throughput Scoping Study Report

43-101

Preliminary Economic Analysis

Ausenco Canada Inc.

November 2009

Summary Report on the CuMo Property,

Boise County, Idaho

43-101

Resource Estimate

Holmgren and Giroux

May 1, 2009

An Investigation into the Recovery of Molybdenum, Copper and Silver from the CuMo Samples

Metallurgical Report

SGS Canada Inc.,

Independent Report

February 18, 2009

Path to Value Creation

Step 1

Step 2

Step 3

Step 4

Step 5

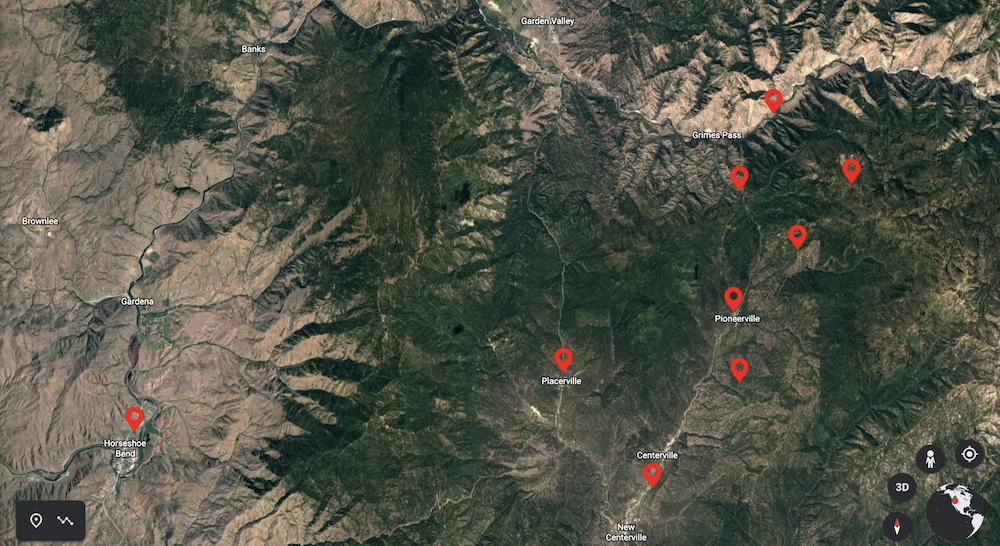

Video Tours

Use our interactive map to view flyover videos of the Idaho Copper Deposit and to tour the vicinity.

Instructions:

1. Use your mouse to hover over the location pin to see the name of the area.

2. Click the area to view a flyover video of that area.

Please note that each time you click on an area, a video will open up in a separate browser and you will navigate off this website.